[ Main page | About Your System | About Fuzzy Logic | The Importance of Explainability | Commercialising ]

I have built a simulation of gas-delivery logistics, showing how this can be controlled by an expert system. As explained on the main page, this is not yet a commercial product but an MVP — Minimum Viable Prototype. However, it demonstrates the principles, and could be scaled up to a commercial product. I have ensured that it needs no specialist knowledge to understand, so it should be easy for the government inspectors to understand and for you to explain to them. For further information about fuzzy logic and how the expert system works, please see About Fuzzy Logic . I explain these at a non-technical level on the current page.

To access the system, please go to https://expertsystemdemos.net/sim_gas.html . Do this on a laptop or desktop computer rather than a phone, as the simulation needs ample screen space for pictures and diagnostics.

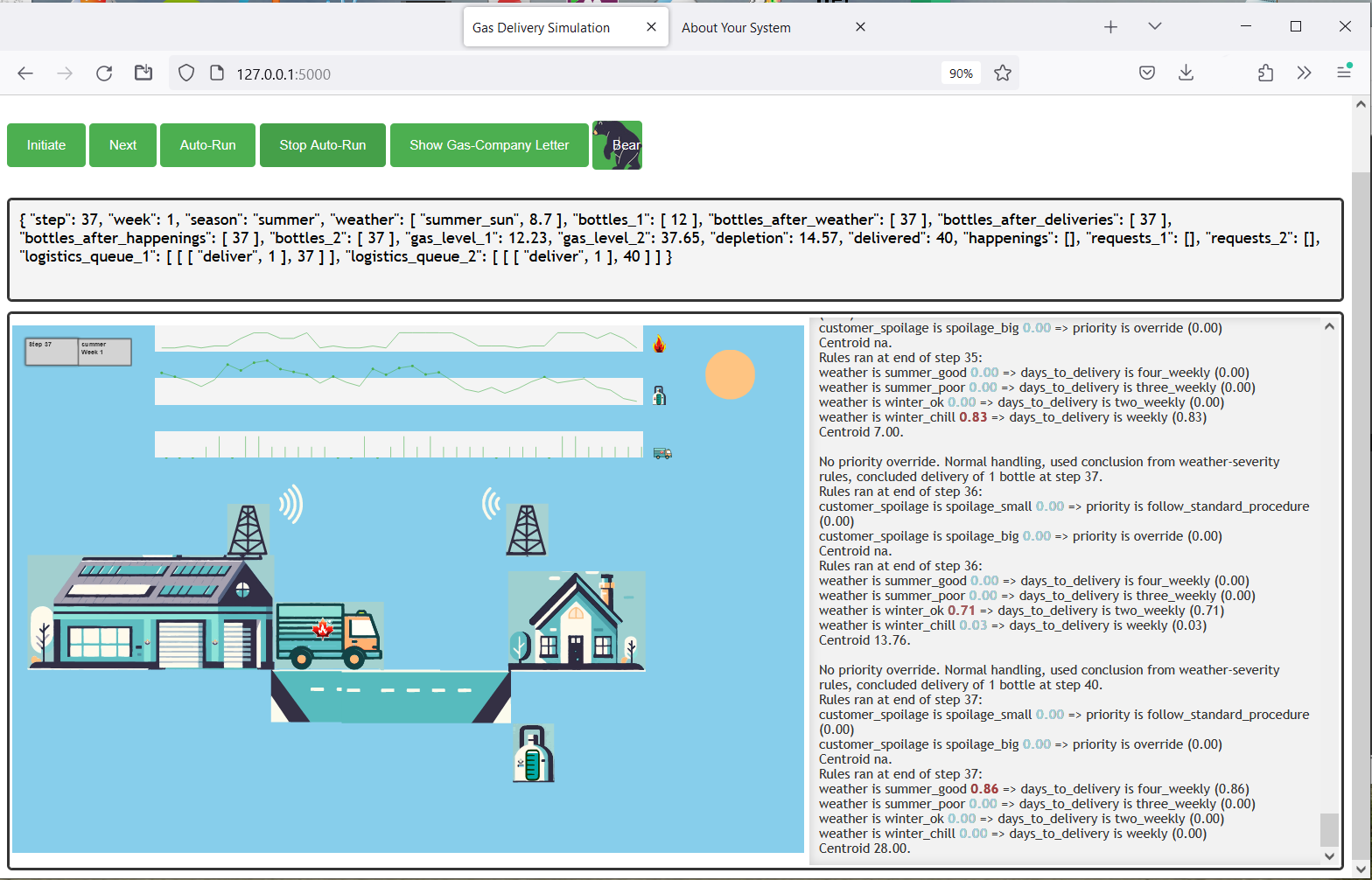

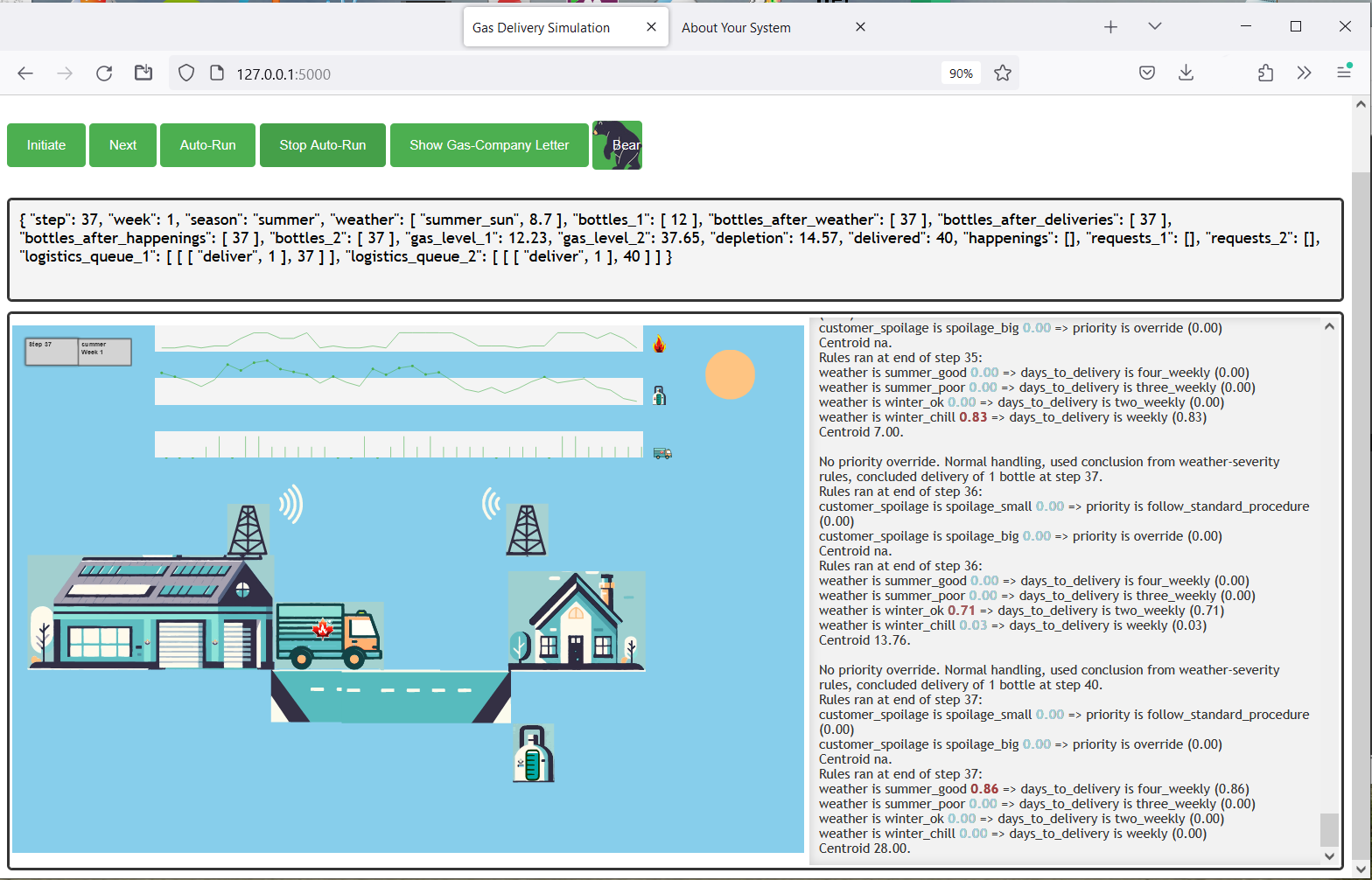

Key elements visible in the simulation are a warehouse,

a house, a road, and a stock of gas bottles.

These reduce the complexities of gas-supply

to their simplest: one company delivering

gas to one householder, whose stocks and situation they

monitor, replenishing via lorry deliveries when

necessary. By influencing gas consumption, the weather, symbolised by

sky colour and by the sun, snow and clouds top right,

also plays a rôle. A typical session is

shown below:

As mentioned above, you should use a desktop or laptop computer. Start up a web browser: I generally use Firefox. Visit the simulation page, https://expertsystemdemos.net/sim_gas.html . You will see some green buttons, an empty text area thereunder, a picture, and an empty "Logistics Rules" panel on its right.

If this is the first time you have run it on this browser in this session, the sky in the picture will be black. If it is blue or grey instead, refresh the page. You may have junk left over from a previous run, which will probably stop things working.

You should now see a black sky. Press `Initiate`. The sky will turn blue or grey, and a weather symbol and some gas bottles will appear. You will also see some programmery-looking text above the picture, some logistics rules on the right, and three short ticker-tape–style graphs plus some figures in the top-left of the picture.

Now press `Next`. The graphs will extend themselves; the figures near them will update; the gas bottles will change; and a new set of logistics rules will scroll into place.

Wait for any action on the screen to stop, then press `Next` again. Do this a few times, watching the picture and the rules.

You could now try an automatic run. Restore the simulation to its resting state by reloading the page. Then press `Initiate`. Then press `Auto-Run`. Wait until at least 12 steps have elapsed, so that you see one complete seasonal cycle. Then press `Stop Auto-Run`.

Next, press `Show Gas-Company Letter`. A welcome letter from the gas company will pop-up, detailing their delivery policy and how this depends on the weather. This will show you how gas stocks are measured, how consumption is affected by weather, and how deliveries are affected by weather.

Finally, scroll back through the logistics rules and consider how they make sense given events in the simulation.

The most important thing is that a gas bottle holds 40 pounds of gas, which I am advised is realistic. In text and in graphics, gas levels are expressed either in numbers of bottles or in pounds. The gas-company letter referred to above uses these units in its explanations.

Time is explained in the following section. Here, the basic unit is a week. Deliveries are scheduled in terms of weeks, and graphs' X axes are marked off in weeks.

Just as films and books use narrative compression to squash down a sequence of events to essentials, so does the simulation. There are two seasons, summer and winter. Each lasts for six weeks, with the winter weather being worse than the summer, and demanding more gas for heating. In screen time, a week passes quickly, in round about five seconds. However, gas usage, as illustrated by the gas-company letter, is meant to be realistic.

The significant timepoints in a week are these:

_1

fields for gas level, contents of bottles,

and other characteristics. These are

visible in the text above the picture. On the picture,

the step number and calendar update.

"weather": [ "summer_sun", 8.91 ] .

High numbers are good weather; low are bad.

logistics_queue_1 . He or she does

this by searching the queue for entries whose step

number is the current step — think of it as

a date — and removing them from the queue.

If there were any, the manager sends them out: you'll

see a lorry drive from the warehouse to the house

and back. The gas bottles under the house then replenish

and the gas-delivery

graph updates.

[ [ "deliver", 1 ], 4 ]

where the first number is an amount of bottles

and the second is a step number. Here, this is

being used in the same way we'd use a date, as

a tag indicating when to do something.

_2

fields for gas level, bottles, and logistics queue. These are

visible in the text above the picture, and will become

the _1 fields for the following week.

This is obviously a very simplified model, which I've adopted for ease and speed of implementation. A more realistic simulation could be built, and might indeed be useful as a teaching aid. Even without the graphics, the internals of such a simulation will be needed as an adversarial environment against which to test your product. However, the current system is easy to explain, and should impress the inspectors by the effort made to produce clean graphics that clearly depict how the rules interact with their environment.

There are three graphs to the right of the step number and calendar. These represent gas consumption, gas level, and gas deliveries respectively. Icons for a flame, a gas bottle, and a lorry are beside them as reminders.

The gas-consumption graph gets updated right at the end of the week, as can be seen by comparing its activity with the other two graphs. It records total consumption for the week: that due to weather plus that due to other events. There is one point per week, drawn midway through the week's stripe.

The gas-level graph gets updated just after the start of the week, once the weather and initial gas-bottle stocks have been depicted. There is one point per week, drawn at the beginning of the week's stripe.

The gas-deliveries graph gets updated on the notional Sunday, at the end of the week. There is one point per week, representing the aggregate of all the week's delivery amounts. Unlike with the other graphs, the plotter does not connect points with lines, drawing instead a vertical line down to the X axis.

In all three graphs, a stripe is 100 pounds high. Remember that a bottle holds 40 pounds, so this is a bit less than two bottles. Entries do sometimes rise above 100, but the scaling has worked pretty well for most test runs. A higher maximum value would make fluctuations in the gas level less obvious, while having different scales for different graphs would make them harder to compare.

Note that there are two

sets of rules: one about whether

to override normal policy, and

one about delivery timing. Note also

that every rule has a condition such

as weather is summer_good

and a conclusion such as

days_to_delivery is four_weekly.

Each condition gets tagged with a coloured number, which is repeated in brackets at the end of the rule.

The number measures how much the condition holds. It's like saying that I, at 6 foot 4 inches, am tall, whereas Eddie at 5 foot 10 inches, is only a bit tall. Or that my shoes, which are 11 in UK sizes, are large, whereas Eddie's, at 7, are average. There is no precise definition of "tall" or "large", and no cut-off point such that 6 foot 4 inches (say) is tall but 6 foot 3 inches is not. Similarly with weather. But we can say, a bit vaguely, that something is 10% tall or 70% big or 90% chilly, and that is what we are doing here. Behind the scenes, a rule-evaluator is handling all this, using fuzzy logic to ensure that these numbers get used in a consistent and mathematically respectable way.

Basically, this is a way of having lots of rules that forecast different aspects of a problem, working out how well each one fits the data, and then integrating all their advice, paying most attention to the rules that fit best. Technically speaking, this is Mamdani fuzzy logic, and is a well-understood part of artificial intelligence, covered in all textbooks. The underlying maths has been around since the 1960s, when it was invented by Lotfi Zadeh. Web searches for topics such as "fuzzy-logic controllers" will find many examples of real- world use: a favourite one is fuzzy control of fans and washing-machines. For more information, see About Fuzzy Logic , especially the shoe-size system demo.

In expert-systems terminology, a

knowledge base is the collection of rules and

other infrastructure that contains the

expert knowledge being consulted. Our

knowledge base is shown below, and contains the rules

seen above plus

their fuzzy sets. Most of

the set membership functions

are triangular, with one or two ascending

and descending. If you remember that

the numbers in the tri,

up and down

structures are positions on the relevant measurement

scale — weather severity, delivery delay, customer

stock loss, or priority — then their meaning should be clear.

Consult the page on fuzzy logic for more info.

As noted in the last section, there are two lots of rules. The priority rules run first. If they decide on an immediate override, then the second lot will either not run, or will run but be ignored. Instead, the logistics manager will queue a request for immediate delivery. Otherwise, the delivery schedule calculated by the second lot of rules will be used.

if weather be summer_good then days_to_delivery := four_weekly. if weather be summer_poor then days_to_delivery := three_weekly. if weather be winter_ok then days_to_delivery := two_weekly. if weather be winter_chill then days_to_delivery := weekly. if customer_spoilage be spoilage_small then priority := follow_standard_procedure. if customer_spoilage be spoilage_big then priority := override. low( weather, 1 ). high( weather, 10 ). scale( weather, '1-10' ). fuzzy_set( weather, winter_chill, tri( 1, 2.5, 5 ) ). fuzzy_set( weather, winter_ok , tri( 3, 4.5, 6 ) ). fuzzy_set( weather, summer_poor , tri( 5, 6.5, 8 ) ). fuzzy_set( weather, summer_good , tri( 7, 8.5, 10 ) ). % Step sets by 2. low( days_to_delivery, 0 ). high( days_to_delivery, 35 ). scale( days_to_delivery, 'Days' ). fuzzy_set( days_to_delivery, immediate , tri( 0, 1, 3 ) ). fuzzy_set( days_to_delivery, weekly , tri( 2.5, 7, 11.5 ) ). fuzzy_set( days_to_delivery, two_weekly , tri( 9.5, 14, 18.5 ) ). fuzzy_set( days_to_delivery, three_weekly, tri( 16.5, 21, 25.5 ) ). fuzzy_set( days_to_delivery, four_weekly , tri( 23.5, 28, 32.5 ) ). % Step sets by 7, sides 4.5. low( customer_spoilage, 0 ). high( customer_spoilage, 400 ). scale( customer_spoilage, 'Pounds' ). fuzzy_set( customer_spoilage, spoilage_small , tri( 0, 2.5, 6 ) ). fuzzy_set( customer_spoilage, spoilage_medium, tri( 4, 15, 20 ) ). fuzzy_set( customer_spoilage, spoilage_big , up( 15, 30, 400 ) ). low( priority, 1 ). high( priority, 10 ). scale( priority, '1-10' ). fuzzy_set( priority, follow_standard_procedure, down( 1, 6 ) ). fuzzy_set( priority, override , up( 4, 10 ) ).

This is obviously simplified compared with real life. I chose a set of rules that was easy for you to explain, maintained stable stock levels over long periods, and was small enough that you could see the entire ruleset in a trace — i.e. in the logistics panel. Nevertheless, they demonstrate the principle, and could be scaled up to a full product.

Running the simulation a number of times will show that the rules maintain stability for quite a long time, without the customer's stocks either crashing to zero or overrunning the available storage space. You can see this in the screenshot shown earlier. It demonstrates, in a simple way, what your final product is to achieve for your customers.